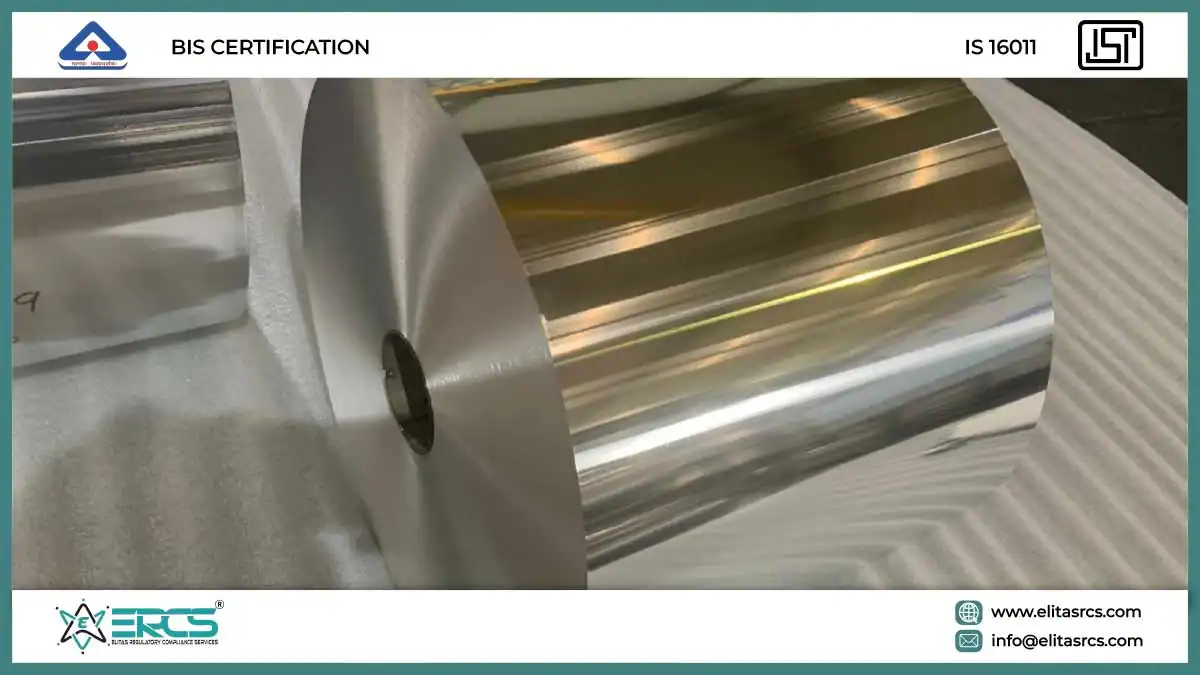

BIS CERTIFICATION FOR ALUMINIUM AND ALUMINIUM ALLOY FOIL FOR PHARMACEUTICAL PACKAGING IS 16011

GET ISI, BIS CERTIFICATION FOR ALUMINIUM AND ALUMINIUM ALLOY FOIL FOR PHARMACEUTICAL PACKAGING IS 16011 : 2012

The first aluminum packaging, caps on glass bottles, date back to the beginning of the 20th century. This was a successful application primarily because the cap could be made to hold tightly to the somewhat irregular glass threads. Aluminum foil was adopted for packaging shortly after its first production in 1913.

Flexible aluminium packaging is often requested by the Pharmaceutical Industry because aluminium has important insulating properties. Aluminium containers used in pharmaceutical sector must be sterile and are generally composed of layered material. In addition, aluminium is highly customizable: coloured or natural, plain or embossed, the pharmaceutical packaging can be supplied according to customers’ needs.

The manufacturing properties of aluminum made it possible to produce such aluminium packaging products by punching, drawing and gluing, as well as by spiral winding foil laminates.

Aluminum for packaging is mainly in the form of sheet or foil. Commercially pure aluminum is mainly used, although non-heat-treatable alloys such as aluminum-magnesium and aluminum-manganese are also used for higher strength. A wide range of mechanical properties is available for both commercially pure aluminum and alloys due to varying degrees of mechanical hardening.

In the glossary of packaging terms, flexible packaging is defined as involving the use of flexible materials such as foil, films, paper, and sheet, to form the container. Aluminum foil has become firmly established as one of the major flexible packaging materials. About 85% of all aluminum foil produced is used in some form of packaging. The three major packaging applications are household foil, 35%; laminated foil, 30%; and formed containers, 28.5%.

Aluminum foil is sheet less than 0.0060 in. (0.15 mm) thick. It can be rolled commercially as thin as about 0.00017 in. (0.005 mm). An important characteristic of aluminum foil is its high covering area per unit of weight.

BIS is a statutory institution established under the Bureau of Indian Standards Act,1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country.

Aluminium and aluminium alloy foil for pharmaceutical packaging product has been specified in IS 16011 : 2012 by Bureau of Indian Standards.

This standard covers the requirements of aluminium and aluminium alloy-bare / coated / laminated foil for pharmaceutical packaging applications. It is applicable for 0.020 mm (20 µm) to 0.040 mm (40 µm) foil thicknesses.

References

The following standards contain provisions, which through reference in this text constitute provisions of this standard. At the time of publication, the editions indicated were valid. All standards are subject to revision and parties to agreements based on this standard are encouraged to investigate the possibility of applying the most recent editions of the standards indicated below:

IS No. Title

737 : 2008 Wrought aluminium and aluminium alloy sheet and strip for general engineering purposes (fourth revision)

5047 (Part 1) : 1986 Glossary of terms relating to aluminium and aluminium alloys: Part 1 Unwrought and wrought metals (second revision)

10259 : 1982 General conditions for delivery and inspection of aluminium and aluminium alloy products.

The uses of aluminum in packaging are identified by the industry in four categories:

- Flexible wraps and laminates, incorporating foil.

- Rigid containers, made from sheet, foil laminates, or drawn heavy-gage. foil, or impact-extruded from slugs.

- Closures for bottles and jars, made from sheet or foil.

- Collapsible tubes, fabricated from slugs by impact extrusion.

Following are the Testing Parameters :

· Material

· Pin Hole Count

· Freedom from Defects

· Average Thickness of Bare foil

· Coating/ Lamination

· Width Tolerance

· Bursting Strength

· Peel Strength

· Sealing Strength

· Lubricant

BIS Certification in India

It is always better to consult with experience team such as ERCS Pvt. Ltd. for smooth certification process.

For more information, please feel free to contact us at info@elitasrcs.com or call at +91-9076611770 / +91-9076611766.

Share:

Article Categories

Latest Blogs

Need Expert Advice?

Feel Free to Connect with Us

Prompt reply within hours

Continued support

Experience Consultants at ERCS are ready to assist you at every step of compliance so as to provide you the best services in India. Get complete information about the certification that your product need to enter in Indian market and build a good consumer base.