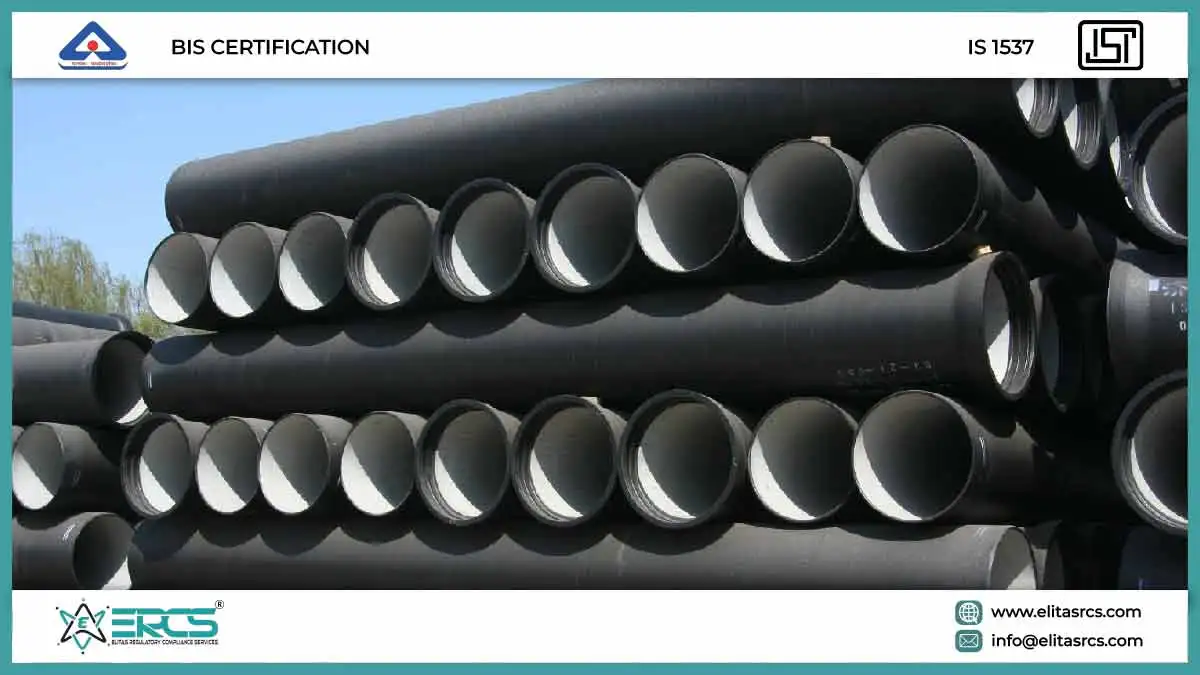

BIS Certification for Vertically Cast-Iron Pressure Pipes for Water, Gas and Sewage IS 1537

GET BIS CERTIFICATION FOR VERTICALLY CAST-IRON PRESSURE PIPES FOR WATER, GAS AND SEWAGE IS 1537:1976

Cast iron pipe is pipe made predominantly from gray cast iron. It was historically used as a pressure pipe for transmission of water, gas and sewage, and as a water drainage pipe during the 17th, 18th, 19th and 20th centuries. In many modern applications, cast iron pipe has been replaced by ductile iron pipe, but this newer product is still often loosely referred to by the older historical name.

The pipes are manufactured by vertical casting in sand moulds. The metal used for the manufacture of this pipe is not less than grade 15. The pipes shall be stripped with all precautions necessary to avoid wrapping or shrinking defects. The pipes shall be such that they could be cut, drilled or machined. The method of Cast Iron pipe production used universally today is to form pipes by spinning or centrifugal action. Compared with vertical casting in sand moulds, the spun process results in faster production, longer pipes with vastly improved metal qualities, a smoother inner surface and reduced thickness and consequent light weight. Centrifugally cast iron pipes are available in diameters from 800mm to 900 mm inclusive and are covered with protective coatings. Pipes are supplied in 3.7 m to 5.5 meters lengths and a variety of joints is available including socket and spigot and flanged joints.

BIS is a statutory institution established under the Bureau of Indian Standards Act,1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country.

Vertically cast iron pressure pipes for water, gas and sewage product has been specified in IS 1537:1976 by Bureau of Indian Standards.

SCOPE :

1.1 This standard covers the requirements for cast iron pipes for pressure main lines of water, gas and sewage manufactured by vertical castings in sand moulds.

1.2 This standard is applicable to pipes with sockets (for lead joints) or flngers. The standard may also be made applicable to other types of joints specially rubber joints, where over all measurements shall be adhered to, to ensure interchangeability.

REFERENCES :

IS 2 :1960 Rules for rounding off numerical values

IS 210 : 1970Specification for grey iron castings

IS 1387 : 1967General requirements for the supply of metallurgical materials

IS 1536 : 1976Specification for centrifugally cast (spun) iron pressure pipes for water, gas and sewage

IS 1789 : 1961 Method for Brinell hardness test for grey cast iron

IS 2078 : 1962 Method for tensile testing of grey cast iron

IS 7184 : 1974Specification for horizontally cast iron double flanged pipes for water, gas and sewage

RAW MATERIALS :

The metal used for the manufacture of pipes shall be of quality not less than Grade 15 of IS 210

TESTING PARAMETERS :

· Manufacture

· Mechanical Tests

o Tensile Test

o Hardness Test

· Sizes, Tolerances, Mass

· Coating

POSSIBLE TESTS IN A DAY :

· All tests are possible to be carried out in a day.

BIS CERTIFICATION IN INDIA

It is always better to consult with experience team such as ERCS Pvt. Ltd. for smooth certification process.

For more information, please feel free to contact us at info@elitasrcs.com or call at +91-9076611770 / +91-9076611766.

Share:

Article Categories

Latest Blogs

Need Expert Advice?

Feel Free to Connect with Us

Prompt reply within hours

Continued support

Experience Consultants at ERCS are ready to assist you at every step of compliance so as to provide you the best services in India. Get complete information about the certification that your product need to enter in Indian market and build a good consumer base.